MIJY-LAND — Customized Pneumatic Tool Solutions

Focused on precision, efficiency, and sustainability to meet diverse production line requirements.

Customized Tool Design Process

From initial requirements to final delivery, every step is tailored to your needs.

-

Customers provide application requirements, including tool speed, torque, fastening components, screw specifications, 3D drawings, and any existing operational issues. STEP.01 -

Sample Preparation

Customers supply actual fastening components and screws used on the production line, serving as the basis for initial evaluation and subsequent design. STEP.02 -

Design & Development

Based on the requirements, design and R&D are carried out. Tool outline drawings are created and submitted to the customer for confirmation. STEP.03 -

Drawing Approval & Order Placement

After drawing approval, Mei-Zhi-Lan schedules production and confirms the delivery lead time. STEP.04 -

Functional Verification

Upon completion, actual fastening operation videos are provided for online review to verify functionality and performance. STEP.05 -

Delivery

After final confirmation, shipment is arranged to ensure on-time delivery and full compliance with application requirements. STEP.06

Every tool specification can be tailored to your requirements

We are committed to creating tools that best match your production line requirements. From appearance to performance, every detail is custom-built exclusively for you.

Torque & Speed

We provide fully customized torque and speed settings that go beyond the limitations of standard market models, precisely tailored to customer requirements to support a wide range of fastening applications and production line needs.

Style & Design

Based on customer-provided fastening components and screw 3D drawings, we design exclusive tool appearances and dimensions rarely found on the market, ensuring a perfect fit for your specific working environment.

Size & Weight

Optimized dimensions and weight are engineered according to actual application scenarios, enhancing handling comfort and improving overall operational efficiency.

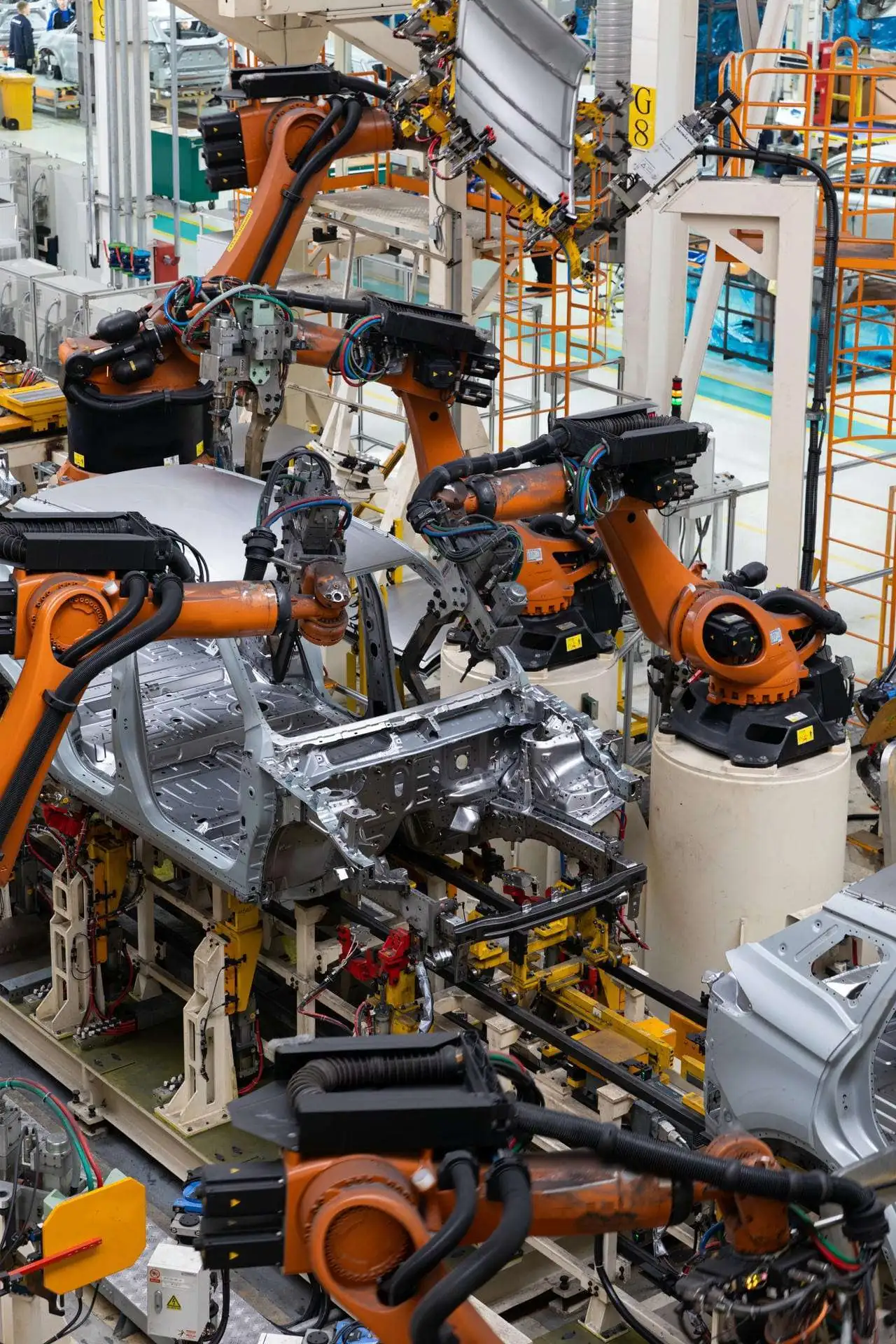

Precision Solutions Across Multiple Industries

MIJY-LAND specializes in the customized design of pneumatic tools, with extensive cross-industry application experience. We have helped numerous manufacturing sites improve production efficiency and fastening quality through tailored solutions.

Construction

Automotive Repair

Aerospace

Precision Manufacturing

Woodworking

Automation Equipment

Expert Team Delivering High-Performance Pneumatic Tools

Professional Team

MIJY-LAND is supported by a multidisciplinary professional team covering R&D, production assembly, maintenance, quality control, and customer service. Through close collaboration, we continuously drive innovation. Our R&D team focuses in particular on customized design and high-precision control, delivering efficient and accurate solutions tailored to customer needs.

Multi-National Patented Designs

MIJY-LAND holds multiple international patents, demonstrating our strong innovation capabilities and leading position in global technology development.

Focused on Production Line Requirements

We continuously refine our designs based on real-world production line demands across various industries. By reducing operator workload and maintaining consistent quality, every product is engineered to precisely match customer requirements—reinforcing MIJY-LAND’s leadership in the industry.