Carbon Fiber Telescopic Torque Arm

Model

Q2000-ZA1, Q2000-ZA2, Q2000-ZA3, Q2000-ZA5

Application

Aerospace Industry Tools

Function

Torque Assist Arm

Product Type

Carbon Fiber Torque Arm

| Material | Product No. | Specifications | Maximum Allowable Torque | Working Distance | Weight | |

| Nm | Base Telescopic Length cm |

Maximum Telescopic Length cm |

Kg | |||

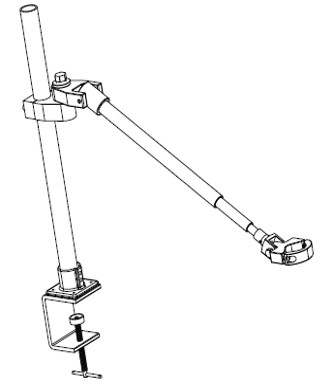

| Aluminum | Q2000-ZA1 | Table Mount Bracket + Support Arm + Aluminum Telescopic Tube | 50 | 4.7 | 105 | 2.9 |

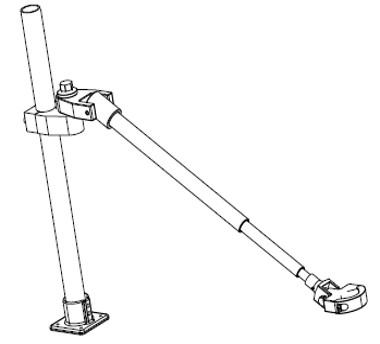

| Q2000-ZA2 | Support Arm + Aluminum Telescopic Tube | 50 | 4.7 | 105 | 1.8 | |

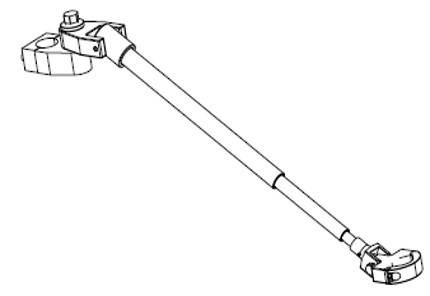

| Q2000-ZA3 | Aluminum Telescopic Tube | 50 | 4.7 | 105 | 1.1 | |

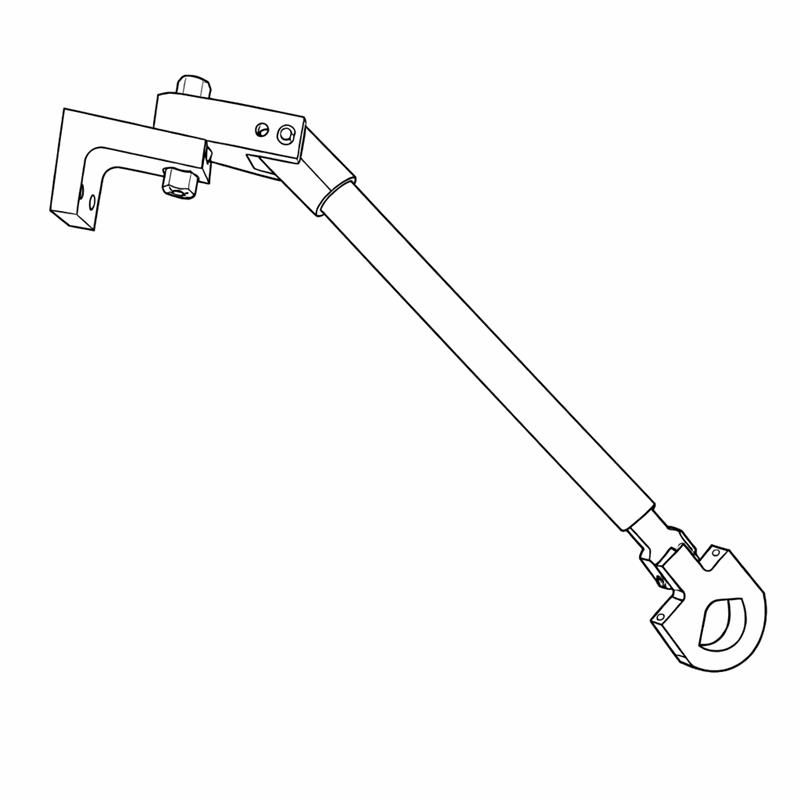

| Q2000-ZA4 | L-Type 2-Hole Mount Base + Aluminum Telescopic Tube | 50 | 4.7 | 105 | 1.1 | |

Suitable for installation on any workstation with a right-angle tabletop edge.

Suitable for worktables with pre-drilled holes for direct mounting.

Suitable for mounting onto existing columns or pillars on the production line.

Suitable for mounting on rails, steel plates, or similar structures; drilling is required prior to installation.

- Suitable for straight, angle, and pistol-type pneumatic or electric screwdrivers.

- Three-stage telescopic design with a minimum working distance of 47.5 cm and a maximum extension of 105 cm.

- Constructed from carbon fiber, offering higher rigidity and greater strength capacity than aluminum.

- Available in four configurations, allowing selection based on production line layout requirements.

- In addition to a fixed tool standby position, the tool can be easily repositioned during operation.

- Reduces reaction force during operation, helping prevent operator injury while improving production line efficiency.

- The use of a torque arm is recommended for straight tools (torque above 3 Nm), pistol-type tools (torque above 12 Nm), and angle tools (torque above 20 Nm) to enhance operator safety.